Introduction

Water parks represent one of the most demanding admission-control environments in the leisure industry. High daily visitor volumes, continuous exposure to water, sunscreen oils, chlorine, and frequent wristband checks create operational challenges that traditional paper or fabric wristbands struggle to handle. For North American water parks, where customer throughput, liability management, and operational efficiency directly impact revenue, admission systems must be fast, accurate, and resilient.

In this context, barcode-compatible vinyl wristbands have become a preferred solution. Unlike Tyvek or fabric alternatives, vinyl wristbands offer superior waterproof performance, strong structural integrity, and reliable compatibility with barcode scanning systems. When integrated with thermal printing wristbands workflows and access control software, they support high-traffic admissions without compromising durability or guest experience.

This article provides an engineering-oriented analysis of vinyl wristbands used in water parks, focusing on material properties, performance characteristics, and system-level integration. A Fulida case study illustrates how optimized wristband design can solve real-world admission bottlenecks in large-scale aquatic venues.

Core Materials Used

Vinyl as a Wristband Substrate

The core material used in water park admission wristbands is soft PVC vinyl, engineered for flexibility, tensile strength, and chemical resistance. Compared with paper-based or woven alternatives, vinyl offers a non-absorbent surface that maintains structural stability even after prolonged immersion.

Vinyl wristbands are typically manufactured using multi-layer PVC construction. The outer layer provides abrasion resistance and print receptivity, while the inner layer ensures wearer comfort and skin safety. For water park applications, latex-free formulations are standard to meet safety and compliance expectations.

Printing and Encoding Compatibility

For barcode-based access control, vinyl wristbands must support high-resolution printing. They are commonly paired with thermal printing wristbands systems, using either direct thermal or thermal transfer technologies. The smooth vinyl surface ensures consistent barcode edge definition, which is critical for fast scanning at turnstiles and attraction checkpoints.

In some deployments, vinyl wristbands are also pre-printed with static branding elements and overprinted on-site with variable data such as admission dates, access zones, or time slots.

Adhesive and Closure Systems

Snap closures or single-use locking buttons are standard for vinyl wristbands in water parks. These closures prevent wristband transfer between guests, an important control point for revenue protection and capacity management.

Material Performance Characteristics

Waterproof and Chemical Resistance

A defining requirement for water park admissions is full waterproof performance. Waterproof vinyl wristbands maintain dimensional stability and print integrity under constant exposure to water, chlorine, salt, and UV radiation. Unlike paper-based wristbands that degrade or delaminate, vinyl resists swelling and ink bleeding.

This performance directly supports reliable barcode scanning throughout the guest’s visit, even after hours of swimming and repeated contact with water slides and pools.

Mechanical Strength and Wear Resistance

High-traffic water parks can process tens of thousands of guests per day. Wristbands are subjected to pulling forces, abrasion against ride surfaces, and frequent inspection by staff. Vinyl’s tensile strength minimizes tearing, while its flexibility reduces stress cracking around closure points.

From an engineering perspective, this durability reduces replacement rates, lowers operational interruptions, and improves guest satisfaction.

Barcode Readability and Scan Accuracy

Barcode compatibility is not only a function of printing quality but also material stability. Vinyl’s low surface porosity ensures that barcodes remain legible and scannable even after prolonged use. This is particularly important for integration with legacy scanners commonly used in North American water parks.

Consistent scan accuracy supports faster queue processing and reduces manual checks, which are prone to human error during peak hours.

Comfort and Safety Considerations

Modern vinyl wristbands are designed to be smooth-edged and skin-friendly. Latex-free formulations minimize allergy risks, while rounded edges prevent irritation during extended wear. These characteristics are essential for family-oriented venues where children make up a significant portion of visitors.

Fulida Case Study — Water Park Admission Systems

Client Background

A large regional water park in the United States experiences seasonal peaks exceeding 12,000 visitors per day. The park operates multiple entry points, locker zones, and restricted-access attractions. Previously, the park relied on Tyvek wristbands with handwritten markings, leading to frequent scanning failures and guest complaints.

Engineering Challenges

The client faced several technical and operational issues:

- Wristbands deteriorated rapidly in wet environments

- Manual admission checks caused congestion during peak hours

- High rates of wristband replacement increased operational costs

- Unauthorized wristband transfers led to revenue leakage

The park required a solution compatible with existing barcode scanners while improving durability and throughput efficiency.

Fulida Solution

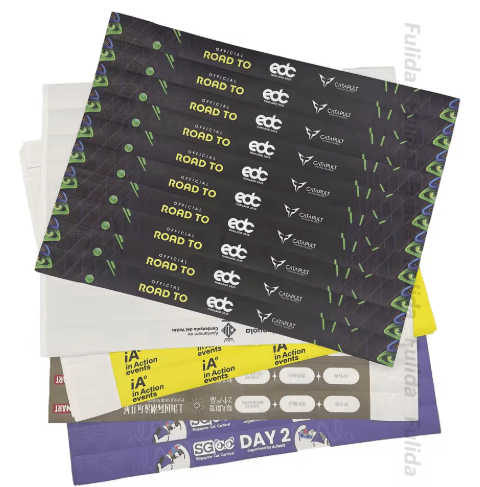

Fulida engineered a barcode-compatible vinyl wristbands solution tailored to water park conditions. The wristbands were optimized for thermal transfer printing, ensuring high-contrast barcodes resistant to water and chemical exposure.

Snap-lock closures were selected to prevent transfer, and wristband dimensions were adjusted to balance durability with wearer comfort. Fulida also provided guidance on printer calibration to maximize barcode readability.

Results and Impact

After deployment, the water park reported measurable improvements:

- Admission processing speed increased by over 30 percent

- Barcode scan failure rates dropped significantly

- Wristband replacement frequency was reduced

- Staff workload during peak hours decreased

The solution supported scalable operations without requiring changes to the existing access control infrastructure.

Material Parameter Table

| Parameter | Vinyl Wristbands Specification |

|---|---|

| Base Material | Soft PVC Vinyl |

| Thickness | 0.25–0.35 mm |

| Waterproof Rating | Fully waterproof |

| Chemical Resistance | Chlorine, sunscreen, saltwater |

| Printing Method | Thermal transfer / direct thermal |

| Barcode Compatibility | 1D and 2D barcodes |

| Closure Type | Single-use snap lock |

| Skin Safety | Latex-free |

Application Scenarios Across Water Parks

In large destination water parks, vinyl wristbands are commonly used for all-day admission passes, enabling repeated access checks without degradation. For multi-day resorts, color-coded or date-encoded barcode wristbands help distinguish guest access levels efficiently.

Wave pools and high-impact attractions benefit from vinyl’s tear resistance, while locker and food service integration allows barcode wristbands to function as cashless identifiers. Seasonal events and special promotions also leverage custom wristband printing to combine branding with operational control.

FAQ

Are vinyl wristbands suitable for children in water parks?

Yes. Latex-free vinyl wristbands are designed for skin safety and comfort, making them suitable for extended wear by children.

Can barcode wristbands integrate with existing scanners?

Most barcode wristbands printed on vinyl are compatible with standard 1D and 2D scanners used in North American water parks.

How long do vinyl wristbands last in wet environments?

When properly printed, vinyl wristbands can maintain structural integrity and barcode readability for multiple days of continuous use.

Is on-site printing required?

Vinyl wristbands support both pre-printing and on-site thermal printing wristbands workflows, depending on operational needs.

Why Choose Fulida

Fulida focuses on material-level engineering rather than generic wristband production. By understanding the environmental stresses of water parks, Fulida designs vinyl wristbands that align with real operational requirements, from barcode readability to mechanical durability.

For North American operators, Fulida provides not only custom manufacturing but also technical guidance on printing systems, material selection, and deployment strategies. This engineering-driven approach helps water parks reduce admission friction, protect revenue, and scale operations during peak traffic periods without compromising reliability.