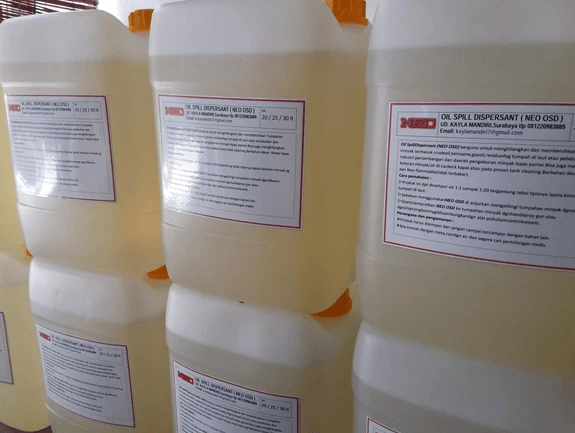

Best Material for Custom Waterproof Sticker Labels

- No Comments

Explore the best materials for custom waterproof sticker labels that ensure durability, tear resistance, and adhesion in harsh environments.

Read More

How to Order Custom Sticker Labels in Bulk: A Practical Guide by Fulida

- No Comments

Ordering custom sticker labels in bulk is a strategic decision for brands, manufacturers, and distributors aiming to control costs, maintain consistency, and ensure supply stability.

Read More

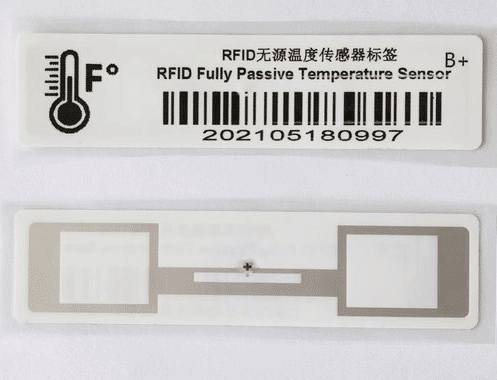

Industrial Barcode Labels: Essential for Asset Tracking, Inventory Management, and Compliance

- No Comments

Explore the advantages of industrial barcode labels for asset tracking, inventory management, and regulatory compliance. These durable, high-performance labels are ideal for warehouse, manufacturing, and logistics operations, ensuring efficiency and accuracy in daily operations.

Read More

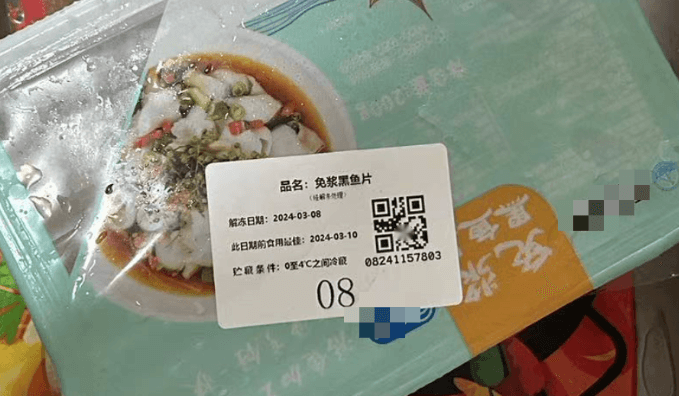

Food Labels: Essential for Compliance, Branding, and Consumer Engagement

- No Comments

Explore the importance of food labels for product identification, regulatory compliance, and consumer engagement. Learn how custom food packaging labels can enhance branding, ensure safety, and meet industry regulations for food manufacturers

Read More

Medical Patient Wristbands: Essential for Identification, Safety, and Workflow Efficiency

- No Comments

Discover how medical patient wristbands enhance patient safety, identification accuracy, and workflow efficiency in healthcare settings. Available in durable, waterproof materials, these wristbands help hospitals and clinics streamline patient management while improving infection control.

Read More

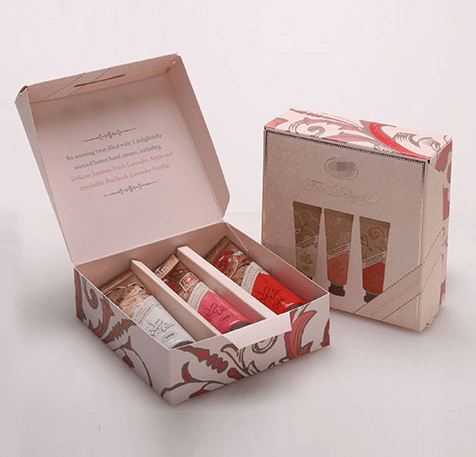

Custom Folding Cartons: Elevate Your Packaging with High-Quality, Customizable Solutions

- No Comments

Explore the benefits of custom folding cartons for your business, offering durable, eco-friendly packaging solutions that enhance product presentation, security, and branding. Perfect for retail, food, cosmetics, and e-commerce packaging needs

Read More