Introduction

Product traceability has become a core operational requirement rather than a value-added feature. In North America, manufacturers, laboratories, healthcare providers, and food producers face increasing pressure from regulatory audits, recalls, quality control systems, and customer transparency expectations. Traditional manual tracking methods and static labeling systems are no longer sufficient.

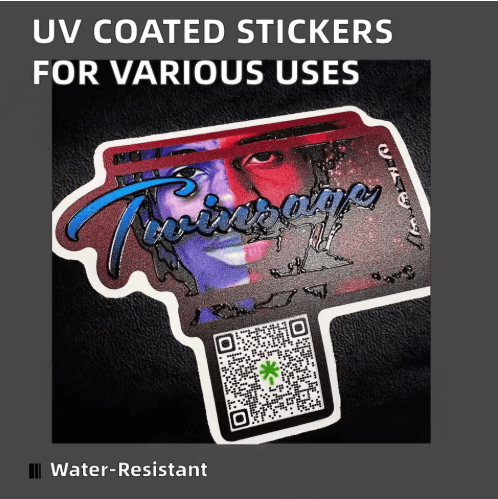

QR codes provide a flexible and data-rich solution for improving traceability across the entire product lifecycle. Unlike linear barcodes, QR codes can store or reference complex datasets, link physical products to digital records, and support real-time updates without changing the physical label.

This article presents an engineering-oriented guide on how to improve product traceability with QR codes, focusing on material selection, printing durability, system integration, and real-world deployment scenarios supported by a Fulida case study.

Core Materials Used

PET Materials for QR Code Labels

PET labels are the most commonly used substrate for QR code-based traceability systems. Polyester offers excellent dimensional stability, which is critical for maintaining QR code module geometry and scan accuracy.

PET materials resist moisture, abrasion, and moderate chemical exposure, making them suitable for manufacturing floors, laboratories, cold-chain food distribution, and healthcare environments. Their smooth surface supports high-density QR code printing without distortion.

Paper-Based QR Code Labels

Paper labels are used for short-term or internal traceability applications such as work-in-progress tracking or temporary logistics identification. While cost-effective, paper materials are sensitive to moisture and abrasion, limiting their use in harsh environments.

Paper QR labels should be restricted to controlled indoor conditions where label lifespan is short.

PVC and Flexible Films

PVC labels are selected when flexibility is required, such as curved packaging or consumer-facing products. Vinyl materials support QR code printing but must be carefully evaluated for heat and chemical exposure to ensure long-term readability.

Adhesive Systems

Traceability labels must remain attached throughout the product lifecycle. Acrylic adhesives are widely used due to their stable performance across temperature ranges and substrates. Adhesive failure directly compromises traceability, regardless of QR code quality.

Material Performance Characteristics

QR Code Readability and Stability

QR code traceability depends on consistent contrast, sharp edges, and stable dimensions. Materials like PET labels maintain print accuracy under environmental stress, reducing scan failures in automated or manual inspection processes.

Even minor label shrinkage or ink bleeding can reduce QR code readability, especially for high-density codes.

Durability Across the Product Lifecycle

Traceability labels are often exposed to multiple environments—from production to storage, transport, and end use. QR code labels must withstand friction, temperature changes, and handling without degradation.

Material durability directly impacts the reliability of downstream traceability data.

Compatibility with Printing Technologies

Most industrial QR code systems rely on thermal transfer labels due to their resistance to smudging, solvents, and abrasion. Digital printing is commonly used for short-run QR labels or when frequent data changes are required.

Matching print technology to material ensures that QR codes remain readable throughout the required traceability period.

Variable Data and Serialization

QR codes enable serialization at the unit, batch, or pallet level. Label materials must support variable data printing without ghosting or fading, ensuring that each QR code reliably links to its unique digital record.

How QR Codes Improve Product Traceability

End-to-End Visibility

QR codes connect physical products to centralized databases. Scanning a code can reveal production date, batch number, test results, compliance documents, and distribution history, supporting full lifecycle traceability.

Real-Time Data Updates

Unlike static barcodes, QR codes can link to dynamic URLs. This allows product information to be updated without relabeling, supporting recalls, compliance updates, and customer communication.

Audit and Recall Readiness

In regulated industries, traceability is critical during audits or recalls. QR codes allow rapid identification of affected products, reducing response time and limiting financial exposure.

Cross-System Integration

QR codes integrate easily with ERP, MES, WMS, and laboratory information systems. This interoperability makes them suitable for complex supply chains involving multiple stakeholders.

Fulida Case Study — QR Code Traceability in Manufacturing and Healthcare

Client Background

A North American manufacturer supplying components to medical device companies required improved traceability to meet customer audit requirements. The company handled thousands of serialized parts across multiple production stages.

Engineering Challenges

The client faced several issues:

- Manual data entry errors in batch tracking

- Label degradation during cleaning and handling

- Limited visibility across production and storage stages

- Increasing audit pressure from downstream customers

Fulida Solution

Fulida implemented a QR code label system using PET labels and thermal transfer labels optimized for chemical resistance and abrasion durability. Each component received a serialized QR code linked to a centralized database.

Scanning points were added at key production and inspection stages, enabling real-time status updates. Label materials were tested to ensure QR code readability after repeated handling and cleaning.

Results and Impact

The system delivered clear improvements:

- Reduced traceability errors and manual data entry

- Faster audit preparation and response

- Improved batch-level and unit-level visibility

- Scalable framework for future regulatory requirements

Material Parameter Table

| Parameter | PET QR Code Labels | PVC QR Code Labels | Paper QR Code Labels |

|---|---|---|---|

| QR Readability Stability | Excellent | Good | Fair |

| Moisture Resistance | Excellent | Good | Poor |

| Print Compatibility | Thermal Transfer, Digital | Digital, Thermal | Digital |

| Typical Traceability Use | Industrial, Medical, Food | Packaging, Retail | Temporary Tracking |

| Lifecycle Durability | Long-term | Medium-term | Short-term |

Application Scenarios Across Industries

In healthcare and laboratories, QR code labels support specimen tracking, patient safety, and compliance documentation. Food manufacturers use QR codes to improve lot traceability and recall efficiency under FDA requirements.

Industrial manufacturers apply QR codes for work-in-progress tracking, quality control, and equipment identification. Events and logistics operators use QR-based systems for inventory visibility and access verification.

FAQ

Are QR codes better than traditional barcodes for traceability?

QR codes store or reference more data and support dynamic updates, making them more suitable for complex traceability systems.

Do QR codes require special scanners?

Most modern scanners and mobile devices support QR code scanning without additional hardware.

How small can a QR code be while remaining readable?

Minimum size depends on data density, print resolution, and material stability. PET materials allow higher-density QR codes.

Can QR codes support regulatory compliance?

Yes. QR codes enhance compliance by improving data access, audit readiness, and recall efficiency.

Why Choose Fulida

Fulida approaches QR code traceability from a systems engineering and material performance perspective. By aligning label materials, printing technologies, and data workflows, Fulida delivers traceability solutions that remain reliable throughout the product lifecycle.

For North American businesses, this means improved compliance readiness, reduced operational risk, and scalable traceability frameworks built on durable, high-performance QR code labeling systems.