Introduction

Food labeling in the United States is governed by strict regulatory frameworks enforced by the Food and Drug Administration. For food manufacturers, co-packers, and private-label brands, non-compliant labels are not simply a documentation issue—they represent a direct risk of product recalls, import detention, and regulatory penalties. In North America, FDA food labeling compliance is a foundational requirement for market access.

Beyond regulatory text accuracy, food labels must maintain legibility and adhesion throughout the product’s lifecycle. Exposure to moisture, refrigeration, freezing, oils, and abrasion can all compromise label performance. As a result, food packaging labels require careful alignment between regulatory content, material selection, and printing technology.

This article presents a structured, engineer-oriented guide to FDA food labeling compliance standards, covering regulatory requirements, material and performance considerations, and a real-world Fulida case study illustrating how compliant labeling systems are implemented in production environments.

PET Materials for Food Labels

PET food labels are widely used for FDA-compliant packaging due to their dimensional stability, moisture resistance, and compatibility with high-resolution printing. Polyester films maintain legibility under refrigeration, condensation, and light chemical exposure from oils or food contact surfaces.

PET materials are particularly suitable for labels carrying regulatory-critical information such as Nutrition Facts panels, ingredient lists, and allergen declarations, where text clarity must be preserved throughout distribution and storage.

Paper-Based Food Label Materials

Coated paper labels remain common for dry food products and short shelf-life items. They offer excellent print quality at a lower cost but are sensitive to moisture and abrasion. Paper labels are typically used when packaging conditions are controlled and exposure risks are minimal.

For FDA compliance, paper labels must still maintain legibility through normal handling, making coating and adhesive selection critical.

PVC and Specialty Films

PVC labels and other specialty films may be used for flexible packaging or curved containers. While cost-effective, PVC must be carefully evaluated for temperature and chemical exposure. In regulated food environments, material selection is often driven by performance rather than cost alone.

Adhesive Systems

Food labeling adhesives must provide consistent adhesion across packaging substrates such as glass, PET bottles, HDPE containers, and metal cans. Acrylic adhesives are commonly used due to their stability across temperature ranges and resistance to moisture.

Adhesives must ensure that labels do not detach or curl, which can obscure mandatory FDA information.

Material Performance Characteristics

Legibility and Print Permanence

FDA regulations require that mandatory labeling information be clearly visible and readable under customary conditions of purchase and use. This includes product name, net quantity, ingredient lists, allergen statements, and Nutrition Facts.

Materials like PET food labels support high-resolution thermal transfer labels and digital printing, ensuring consistent text sharpness and barcode readability.

Resistance to Environmental Exposure

Food labels are routinely exposed to refrigeration, freezing, condensation, oils, and friction during transport. Materials must resist ink bleeding, label wrinkling, and adhesive failure.

Failure to maintain label integrity can result in partial loss of FDA-required information, leading to compliance violations even if the original content was correct.

Compatibility with Printing Technologies

FDA-compliant food labels are commonly produced using digital printing for short runs and thermal transfer labels for high-durability applications. Thermal transfer printing offers superior resistance to moisture and abrasion, making it suitable for cold-chain and long-shelf-life products.

Traceability and Variable Data

Batch codes, lot numbers, and expiration dates are often required for traceability. Label materials must support variable data printing without smudging or fading, ensuring that traceability information remains intact for the product’s full lifecycle.

FDA Food Labeling Compliance Requirements

Mandatory Label Elements

Under FDA regulations, food labels must include specific elements:

- Statement of identity

- Net quantity of contents

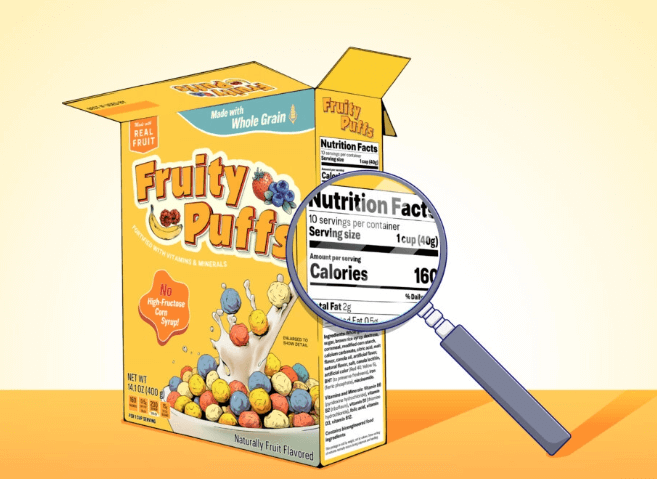

- Nutrition Facts panel

- Ingredient list in descending weight order

- Allergen declarations

- Name and address of the manufacturer, packer, or distributor

These elements must be presented with minimum font sizes, contrast, and placement requirements to ensure visibility.

Nutrition Facts Label Standards

The Nutrition Facts label must follow FDA-prescribed formatting, including typeface hierarchy, line spacing, and standardized nutrient declarations. Errors in layout or legibility can trigger regulatory action even if the data itself is accurate.

Allergen Labeling Compliance

Major food allergens must be clearly declared using standardized language. Label durability is critical, as allergen information must remain readable through handling and storage to protect consumer safety.

Language and Accuracy Requirements

FDA standards require truthful and non-misleading labeling. Claims such as “natural,” “organic,” or nutrient content claims must be substantiated and accurately presented. Label materials must support consistent reproduction of approved content across production runs.

Fulida Case Study — FDA-Compliant Food Labeling Implementation

Client Background

A North American packaged food manufacturer producing refrigerated sauces and ready-to-eat meals required FDA-compliant labels for multiple SKUs. The products were distributed through national retail chains and subject to routine audits.

Engineering Challenges

The client faced several issues:

- Label wrinkling and adhesive failure under refrigeration

- Fading of Nutrition Facts text due to condensation

- Inconsistent barcode scan rates at retail checkout

- Frequent regulatory updates requiring short-run label changes

Fulida Solution

Fulida specified PET food labels combined with acrylic adhesives optimized for cold and moist environments. Thermal transfer labels were selected to ensure print permanence for regulatory text and barcodes.

Digital printing was used for short-run regulatory updates, allowing rapid changes without tooling delays. Fulida also validated label adhesion and legibility under simulated refrigeration and handling conditions.

Results and Impact

The solution delivered measurable benefits:

- Consistent FDA compliance across all SKUs

- Improved label durability throughout cold-chain distribution

- Reduced relabeling and compliance risk

- Faster response to regulatory and formulation changes

Material Parameter Table

| Parameter | PET Food Labels | Paper Food Labels | PVC Labels |

|---|---|---|---|

| Moisture Resistance | Excellent | Low | Good |

| Print Durability | High | Medium | Medium |

| FDA Compliance Suitability | High | Conditional | Conditional |

| Printing Compatibility | Digital, Thermal Transfer | Digital | Digital, Thermal |

| Typical Use | Refrigerated, Frozen Foods | Dry Goods | Flexible Packaging |

Application Scenarios Across the Food Industry

In refrigerated and frozen food categories, FDA compliance labels made from PET ensure legibility despite condensation and temperature variation. Dry food manufacturers often use coated paper labels where exposure risks are minimal.

Co-packers and private-label brands rely on short-run custom food label printing to accommodate frequent regulatory updates and retailer-specific requirements. Across all scenarios, material performance directly impacts compliance outcomes.

FAQ

Does FDA regulate label materials or only label content?

FDA primarily regulates content and legibility, but material performance affects compliance if required information becomes unreadable.

Are thermal transfer labels necessary for food packaging?

Not always, but thermal transfer labels are recommended for cold-chain or high-abrasion environments.

How long must FDA-required information remain legible?

Mandatory information must remain legible throughout the product’s normal shelf life and handling conditions.

Can short-run labels meet FDA standards?

Yes. With proper material and printing selection, short-run labels can fully comply with FDA requirements.

Why Choose Fulida

Fulida approaches FDA food labeling compliance standards from a material engineering and production reliability perspective. By aligning regulatory requirements with real-world packaging conditions, Fulida delivers labeling systems that remain compliant throughout distribution and use.

For North American food manufacturers, Fulida provides consistent material quality, printing expertise, and rapid response to regulatory changes—helping reduce compliance risk while maintaining operational efficiency.