Introduction

Cold chain compliance is a critical control point in pharmaceutical and biopharmaceutical distribution. Vaccines, biologics, injectable drugs, and temperature-sensitive APIs must remain within tightly controlled environmental conditions from manufacturing to final administration. While temperature monitoring has become highly standardized, moisture exposure remains an underestimated risk factor during packaging, warehousing, and international transportation.

Condensation inside insulated shippers, humidity ingress during customs inspections, or improper storage conditions can compromise packaging integrity and, in severe cases, drug stability. Traditional electronic data loggers capture temperature trends but often fail to provide immediate visual evidence of moisture contact at the unit or carton level.

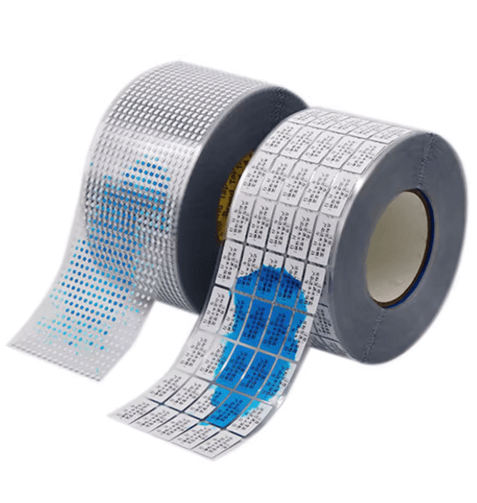

This gap has driven increasing adoption of Custom Water Sensitive Stickers as a passive, tamper-evident, and cost-effective validation tool in pharmaceutical packaging systems. These indicators offer instant visual confirmation of water or condensation exposure, enabling quality teams to identify non-compliant shipments before products enter clinical or commercial use.

Core Materials Used

Custom Water Sensitive Stickers are engineered using multilayer material systems designed to react reliably to liquid water while maintaining stability in dry environments common to pharmaceutical cold chains.

The core construction typically includes a moisture-reactive coating layer applied to a high-stability substrate. Common substrate options include PET films and coated paper engineered for dimensional stability under low temperatures. PET is often preferred in pharmaceutical environments due to its chemical resistance, low moisture absorption, and compatibility with validated packaging systems.

The reactive layer is formulated using water-soluble dyes or microencapsulated pigments that undergo irreversible color change upon direct contact with liquid water. This ensures that once activated, the visual indicator cannot revert, preserving audit integrity.

Adhesive selection is equally critical. Acrylic-based pressure-sensitive adhesives are commonly used to ensure reliable bonding to cartons, insulated shippers, foil pouches, and secondary packaging without adhesive bleed or delamination under cold chain conditions.

In regulated environments, all materials used in Custom Water Sensitive Stickers must be compliant with indirect contact packaging standards and demonstrate low extractables and leachables risk.

Material Performance Characteristics

The functional value of Custom Water Sensitive Stickers lies in their engineered performance balance between sensitivity, stability, and readability.

Moisture sensitivity is precisely calibrated to react to liquid water or condensation rather than ambient humidity. This prevents false positives during high-humidity but compliant transport conditions. Reaction thresholds are validated through controlled condensation testing rather than simple RH exposure.

Low-temperature performance is another key parameter. Pharmaceutical cold chains frequently operate between 2°C and 8°C, with some biologics requiring frozen conditions. High-quality indicators maintain adhesive strength, substrate flexibility, and color clarity without cracking or fogging at reduced temperatures.

Visual contrast is optimized to ensure that activation is clearly detectable during incoming inspection. Strong color transitions enable rapid decision-making by warehouse operators, QA inspectors, and pharmacists without specialized equipment.

Equally important is long-term stability. Unactivated stickers must remain unchanged throughout extended storage cycles, often exceeding 12–24 months, aligning with pharmaceutical shelf-life expectations and packaging validation timelines.

fulida Case Study — Biopharmaceutical Cold Chain Packaging Validation

A mid-size biopharmaceutical company specializing in injectable biologics faced recurring challenges during international shipment of clinical trial materials. Despite using validated insulated shippers and electronic temperature loggers, several shipments were quarantined due to suspected condensation inside secondary packaging.

The quality assurance team required a solution that could provide immediate, shipment-level evidence of moisture exposure without introducing electronic complexity or regulatory revalidation of existing packaging configurations.

The engineering challenge involved selecting a moisture indicator that would not trigger under normal cold chain humidity but would reliably activate if condensation occurred due to temperature excursions or improper handling.

fulida developed a Custom Water Sensitive Sticker solution tailored for pharmaceutical packaging validation. The indicator was engineered with a PET substrate, a calibrated moisture-reactive layer, and a low-temperature acrylic adhesive compatible with insulated shipper liners.

Through controlled condensation chamber testing, fulida validated the activation threshold and ensured zero false positives under compliant conditions. Stickers were placed at critical moisture risk points inside secondary cartons and outer shippers.

Following implementation, the client achieved faster incoming inspection decisions, reduced unnecessary quarantines, and strengthened their cold chain documentation for regulatory audits. The visual evidence provided by the Custom Water Sensitive Stickers became an integral part of their packaging validation protocol.

Material Parameter Table

| Parameter | Specification |

|---|---|

| Substrate Material | PET Film or Coated Paper |

| Reactive Layer Type | Water-soluble dye based coating |

| Activation Trigger | Direct liquid water or condensation |

| Color Change | Irreversible, high contrast |

| Operating Temperature | −20°C to +40°C |

| Adhesive Type | Acrylic pressure-sensitive |

| Adhesion Surface | Carton, foil, insulated liner |

| Shelf Life | 18–24 months (unactivated) |

| Compliance | Indirect pharmaceutical packaging compatible |

Application Scenarios Across Pharmaceutical Cold Chains

In pharmaceutical manufacturing facilities, Custom Water Sensitive Stickers are commonly used during packaging validation trials to identify condensation risks within newly designed shipper configurations.

In clinical trial logistics, these indicators support chain-of-custody assurance by allowing depots and sites to visually verify shipment integrity before acceptance.

For commercial distribution, they are applied to secondary packaging and palletized loads to support GDP compliance and reduce dispute resolution time between manufacturers, logistics providers, and distributors.

Biopharmaceutical companies shipping high-value biologics benefit from combining electronic temperature loggers with Custom Water Sensitive Stickers, creating a layered monitoring strategy that addresses both thermal and moisture risks.

FAQ

How do Custom Water Sensitive Stickers differ from humidity indicators

They respond specifically to liquid water or condensation rather than ambient humidity, reducing false positives in compliant cold chain environments.

Can these stickers be used with frozen pharmaceutical products

Yes, properly engineered indicators maintain performance at sub-zero temperatures and activate upon thaw-related condensation events.

Are Custom Water Sensitive Stickers reusable

No. Activation is irreversible by design to preserve audit integrity and prevent tampering.

Do they replace electronic data loggers

They complement data loggers by providing immediate visual evidence of moisture exposure at the package level.

Are they compatible with pharmaceutical regulatory requirements

When properly specified, materials and adhesives are suitable for indirect pharmaceutical packaging and support GDP and packaging validation documentation.

Moisture exposure remains a hidden risk within pharmaceutical cold chains, often undetected until packaging integrity is compromised. Custom Water Sensitive Stickers provide a simple yet highly effective visual validation tool that enhances cold chain compliance without adding electronic complexity.

By integrating these indicators into pharmaceutical packaging validation strategies, manufacturers and biopharmaceutical companies gain faster inspection workflows, stronger audit readiness, and improved shipment confidence across global distribution networks.